Fabrication is the process used to manufacture steelwork components that will, when assembled and joined, form a complete frame. The frame generally uses readily available standard sections that are purchased from the steelmaker or steel stockholder, together with such items as protective coatings and bolts from other specialist suppliers.

Although a wide range of section shapes and sizes are produced, the designer may find that the required section size is not available. In this case, built-up girders may be fabricated from plate. Sections and plate girders may also be strengthened by stiffening the web or flanges depending upon the load to be carried.

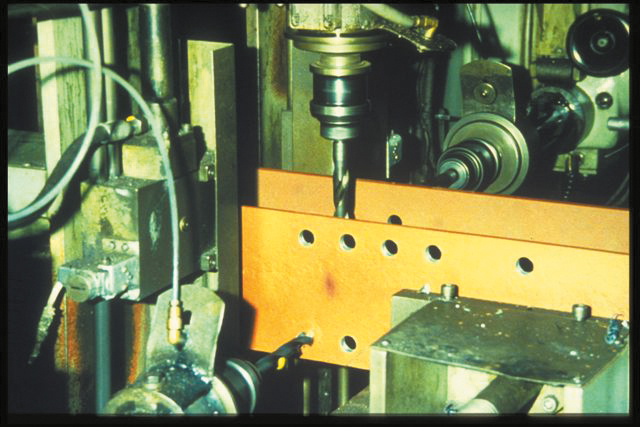

Most modern steelwork fabrication factories have computer aided design and detailing (CAD) which is linked directly to factory floor computer numerically controlled (CNC) machinery creating a genuine CAD/CAM environment. The accuracy of the computer generated details being transmitted directly to the computer aided manufacturing (CAM) machinery increases the quality standards of production

The fact that machinery has taken over from the tape measure means that the frame is produced to high quality standards which are reflected in the speed and accuracy of steel erection on site. This results in significant benefits both to the client and main contractor.

(Image courtesy of Paddy Wall & Sons)

Design for economic fabrication

There are a number of general "technical" factors to consider in terms of design for economic fabrication that apply to most building projects. Some relate to the complexity of the particular project, whilst others are specific to the type of project, e.g. multi-storey, portals, trusses.

Specification

Conformance with the National Structural Steelwork Specification for Building Construction (NSSS) will reduce uncertainty. Additional project specific clauses, more demanding tolerances, and additional testing will increase costs.

Bay size

(Image courtesy of Kingspan Structural Products)

Structural steel frames must have the required degree of lateral resistance to wind loads. This can be provided by a stiff core or by the frame itself - diagonal steel bracing is usually a less expensive solution than moment frames.

Complexity

Modern CNC fabrication equipment can cope with complex individualistic designs but, in general, the more complex the fabrication the greater the cost. Fabrication is more economic with:

- Single square end cuts

- One hole diameter on any one piece avoids drill bit changes

- Holes in flanges and webs aligned where possible

- Web holes having adequate flange clearance

- Rationalised range of fittings for connections

- The use of a small range of standard bolts, e.g. M20 grade 8.8 for shear connections

Wherever possible, leave the choice of the connection detail to the steelwork contractor as the type and design of connections directly influences the total frame cost. Rationalise the range and tonnages of section sizes used.

Complex individualistic designs are going to cost more per tonne, even with modern CNC equipment. If you wish to keep costs down - keep it simple!

Materials

Avoid mixing steel grades where possible and rationalise the range of section sizes / tonnages used in order to minimise cost, lead times and factory handling. In general steel grade S355 offers greater economy unless stiffness / deflection governs the design, in which case S275 should be considered.

(Image courtesy of Billington Structures Ltd.)

Architectural influence

Ensure that unnecessary finishing is not specified and that any applied corrosion resistant coating is appropriate for the environmental conditions to be encountered. Grinding of welds to improve the appearance of the steel is usually only required for exposed steel in close proximity to a building’s occupants.

Quality of engineering and documentation

Completeness and accuracy of information are vital for a steelwork contractor to be able to properly assess the work involved. Where the steelwork is pre-designed, ensure that all member sizes are shown and that the connection forces are shown or are available. Guidance on identifying the requirements for the production and exchange of accurate, timely and detailed information for projects involving steelwork is available in BCSA publication no. 45/07.

Further guidance on the design of buildings for economic fabrication is available in:

- BCSA publication Steel Buildings, Chapter 11 - Fabrication

- The Steel Designer’s Manual, Chapter 33 - Fabrication

- SCI publication P150 Design for Manufacture Guidelines

Guidance on the design for economic fabrication of bridges is available in BCSA publication Steel Bridges, Chapter 7 - Costs.

Materials and components

Steel sections and plate, structural bolts, welding consumables, light gauge decking and corrosion protection and fire protection systems are all manufactured to British standards (issued as BS EN) and in many cases are UKCA marked (or CE marked until 30 June 2025). In addition to these materials, steel fabrication also needs fabrication equipment (e.g. cutting, sawing, drilling, welding machines etc.) and software (e.g. for computer controlled machinery).

Sections and plates

(Image courtesy of Rainham Steel Company Ltd.)

Large orders can be supplied direct from the steel mills, but Steelwork Contractors normally obtain their steel sections and plates from a steel stockholder. Steel stockholders play a vital part in the steel construction supply chain, ensuring that the market is supplied with what it needs when it is needed. The industry has an extensive network of depots serving all parts of the country. The stockholders provide a range of products to the construction industry including heavy structural sections, plates, light sections, cladding materials, flats, angles. Total stocks held represent about 40 days supply. All BCSA stockholder members have quality management systems such as BS EN ISO 9001[4] in place supplemented by individual identification systems to ensure full traceability from the steel manufacturer to the steelwork contractor.

Bolts

Although the majority of structural bolts are manufactured outside of the UK they are all UKCA marked (or CE marked until 31 December 2021) and are manufactured to British standards – BS EN 14399[5] for preloaded bolts and BS EN 15048-1[6] for non-preloaded bolts. The exacting quality control requirements placed on manufacturers and distributors by the BCSA ‘Model Specification for the Purchase of Structural Bolting Assemblies and Holding Down Bolts’ ensures the quality of structural bolts placed on the UK market by BCSA bolt distributors.

Proprietary products

Proprietary products such as some cellular beams, fasteners, purlins, cladding and roofing systems are also available and can provide novel and cost effective alternative solutions.

Coating systems

Paint systems, galvanizing and other protective coatings have developed over the years in response to numerous technological advancements that have brought improved performance and comply with industrial environmental legislation. Manufacturers are conscious of their position in the supply chain and the demands by industry for best service.

Cold-formed sections

(Image courtesy of Caunton Engineering Ltd.)

Fabrication processes

(Image courtesy of Parker Steel)

Preparation

Stockyard

The steel fabrication story begins as the basic sections and plates are delivered to a storage area, or steel stockyard. Here it is unloaded and stored prior to being moved to the fabrication lines for processing. Fabrication is a rapid process, and whilst a typical stockyard may contain several thousand tonnes of material, that is only enough to keep the fabrication lines supplied for a few weeks.

The stockyard

Shot blasting

For many Steelwork Contractors, sections and plates are shot blasted prior to fabrication, although some chose to carry out the shot blasting after the sections are cut to length. This surface preparation is an important part of the fabrication process, which is essential to provide a suitably clean finish for welding and subsequently also to produce a keyed surface ready to accept paint. Shot is fired at the steel. The force of the shot against the surface displaces dirt and scale, and also indents the steel creating a "rough" surface, approx. 70 microns deep. When paint is sprayed onto this clean abraded surface it adheres well and provides a longer life for the paint system.

Prefabrication primers can be applied, immediately after blast cleaning, to maintain the reactive blast cleaned surface in a rust free condition through the fabrication process until final painting can be undertaken.

Shot blasting

Cutting & drilling

In the fabrication factory one of the first operations is to cut the sections to length and profile the plates to the desired size or shape. This can be done in a number of ways using a range of automated machinery:

Circular saws

(Image courtesy of Kiernan Structural Steel Ltd.)

Saw cutting

Gas or flame cutting

(Image courtesy of Kiernan Structural Steel Ltd.)

Flame cutting

Plasma cutting

Components can also be cut efficiently by plasma arc systems. A fine bore, copper nozzle constricts the arc between the electrode and the work piece. This increases the temperature and velocity of the plasma emanating from the nozzle. The temperature of the plasma is in excess of 20,000°C and the velocity can approach the speed of sound. When used for cutting, the plasma gas flow is increased so that the deeply penetrating plasma jet cuts through material whilst molten material is removed in the efflux plasma.

Plasma cutting

Drilling and punching

Punching can be used where the thickness of the metal is less than the diameter of the hole or in the case of a non-circular hole its minimum dimension (Note that the 15mm thickness limit for punching mentioned in the video clip below no longer applies). In the punching process a cutting punch is forced under pressure through the steel into a die below, so producing a clean, accurately sized, hole. Where fatigue is an issue the holes are punched 2mm undersized and reamed to the correct diameter.

Drilling and punching

Bending

Where feature steelwork or curved structural steelwork is required, the steel will be sent to a specialist fabricator. Here through the use of roller bending or press braking equipment, curves and bends can be created. Design considerations relating to the use of curved members are explained in the Design of Curved Steel (P281), which covers the theory and also gives examples of curved steel in buildings. Further information can be sourced from well known bending companies.

(Image courtesy of Kloeckner Metals UK Westok)

Section bending

(Image courtesy of Barnshaw Section Benders Ltd.)

Section bending

Plate bending

Plate bending is similar to section bending but the bending rolls are horizontal and are longer. Plate is fed in flat and on each pass through the rolls, more curvature is introduced and the process is repeated until the desired curvature is achieved.

Plate bending

Tube bending

Tube bending is carried out in a similar way to section bending. Generally, a tube is stronger than its equivalent size beam so, to bend it, more force is required. During bending the outer profile of the tube is supported by sets of machined rolls.

Tube bending

Press breaking

A wide variety of shapes can be formed from profile cut or sheared plates. Sometimes these shapes are required at 12 metres long (or more). To achieve this a ‘Press Breaking’ process is used to press the steel along its entire length.

Press breaking

Tee splitting

Flame cutting is used to make tee sections from beams. This involves the use of a burning torch on a trolley arrangement that runs up the beam until the cut is completed. The beam can be cut centrally; off-centre or the flanges can be trimmed. The Tee section needs to be straightened after splitting, this is due to the stress being released after the cut.

Tee splitting

Profiling of tubular sections

In addition to the standard fabrication processes common to all structural elements, tubular sections may require profile-shaping or saddling. Profile-shaping is required where the end of a tubular section has to fit the contour of a curved surface on a circular hollow section main member. This type of connection can be most commonly seen on tubular trusses

Profiling tubes

Welding

Main article: Welding

Welding is a core activity in the fabrication factory; it is used to prepare joints for connection on site and for the attachment of other fixtures and fittings. Different welding techniques are used for different activities within the fabrication factory.

Essentially, the welding process uses an electric arc to generate heat to melt the parent material in the joint. A separate filler material supplied as a consumable electrode also melts and combines with the parent material to form a molten weld pool. The weld pool is susceptible to atmospheric contamination and therefore needs protecting during the critical liquid to solid freezing phase. Protection is achieved either by using an inert shielding gas, by covering the pool with an inert slag or a combination of both actions. As welding progresses along the joint, the weld pool solidifies fusing the parent and weld metal together. Several passes or runs may be required to fill the joint or to build up the weld to the design size

Assembly and welding requires skilful operatives and will generally be the largest element of the fabrication costs. Welding requires the steelwork contractor to have in place a welding quality management system to BS EN ISO 3834[7] under the control of a Responsible Welding Coordinator. UKCA marking of fabricated steelwork to BS EN 1090-1[8] requires the steelwork contractor to have in place a certified Factory Production Control system in line with BS EN 1090-1[8] which is supported by the British standard for Execution of steelwork, BS EN 1090-2[9].

Manual Metal Arc welding (MMA)

MMA or ‘Shielded metal arc’ welding is used to temporarily join or tack weld components during fabrication prior to full strength welding. Shielded metal arc welding employs a "Stick" type electrode covered with a flux coating. The electrode is brought into contact with the work piece and an electric arc between the electrode tip and the work piece is struck. The flux coating on the welding rod is heated to a gas and liquid. This shields the molten puddle from the atmosphere, hence its name - Shielded metal arc welding.

Manual metal arc welding (MMA)

Metal Active Gas welding (MAG)

(Image courtesy of Kiernan Structural Steel Ltd.)

Metal-active gas welding (MAG)

Submerged Arc Welding (SAW)

(Image courtesy of Mabey Bridge Ltd.)

Submerged arc welding (SAW)

Non Destructive Testing (NDT)

Non destructive testing is carried out to ensure that welds are free from unacceptable defects such as cracks and inclusions. The main NDT techniques are magnetic particle inspection (MPI), and ultrasonic testing. MPI utilises a magnet and a magnetic liquid on the surface of the weld, and ultrasonic testing involves sending sound waves through the weld and interpreting the resulting echo pattern on an oscilloscope

Non-destructive testing

Coating

(Image courtesy of Hempel UK Ltd.)

Coating application

Generally, the emphasis for buildings is on simple systems that are easy to apply involving spray application after automatic blasting. Many fabrication facilities have internal atmospheres that enable the steel to be blast cleaned before fabrication and surface coated afterwards. In such cases, the weld areas would require further surface preparation before coating, and components that are not too bulky can be re-blasted by passing them through the automatic blasting machine on a conveyor. Larger components would have to be manually blasted. To minimize this double handling, it makes economic sense to keep some components with no welding as these would not require re-blasting before coating application.

Access for painting is difficult for double angle or double channel members and these types of elements have now been largely superseded by using Square Hollow Section (SHS) / Rectangular Hollow Sections (RHS) members that reduce the painted area and provide fewer locations for corrosion traps to form.

Accuracy

Modern steel fabrication involves the manufacture of large and often complex welded assemblies of rolled steel products. High temperature processes are used to make the steel products, to form the components and to join them together, so dimensional variation resulting from distortion is inherent and unavoidable.

Dimensional variation is significant in a number of ways, for it involves structural steelwork manufactured remote from the site, civil engineering works at the site, and sometimes even precise mechanical components. These interface with each other and yet their precision varies from the high accuracy of mechanical components to the approximation inherent in placing concrete.

For each new project, the steelwork contractor will assess the design to determine how best to undertake the fabrication to control dimensions and achieve the required accuracy of steel fabrication to ensure proper fit-up and assembly at site.

A thorough understanding of the causes of fabrication distortion, and experience in the control and correction of distortion allows the Steelwork Contractor to work within standard fabrication tolerances, such as those defined in the NSSS. For particularly complex fabrications, trial erection can be carried out to ensuring that fit-up and geometry can be achieved at site, so reducing the risk of delays in erection or damage to protective treatment. However, with the much-improved accuracy achieved by automated fabrication procedures, the need for trial erection has been much reduced.

Handling and transportation

(Image courtesy of Mabey Bridge Ltd.)

- Health and Safety in the Workshop for Employees: A Guide for Steelwork Contractors,

- Guide to Work at Height during the Loading and Unloading of Steelwork

There are three regimes for the transportation of steelwork on the UK road network:

Normal loads

Vehicles with rigid vehicle length less than 18.65 m, width less than 2.9 m, gross weight less than 44 tonnes, with no axle weight over 11.5 tonnes, and overall height less than 4.95 m can travel anywhere at any time, except where the route includes an underbridge with weight restriction or an over-bridge with height restriction. In the case of transportation of bridge girders, rigid vehicle length is usually the girder length. Although the height limit is 4.95 m, the trailer bed is usually about 1.7 m high so that leaves only 3.25m for the load above.

Abnormal loads

(Image Courtesy of Mabey Bridge Ltd.)

There are three categories of STGO vehicles, each with different weight limits, but all three have a maximum vehicle length of 30m and width of 5m. Each police authority on the planned route has to be notified at least 2 days in advance, and it is also necessary to notify bridge owners on the route if the weight exceeds 44 tonnes.

Often the police will not insist on escorting loads that are long and not wide as these cause far fewer manoeuvrability problems. Even with wide loads the number of times the police insist on escorting them has reduced since the Department of Transport introduced the 'Code of Practice: Lighting and Marking for Abnormal Load Self escorting vehicles incorporating Operating guidance’[11]. Where the police do insist on escorting loads, the notification / escort arrangements must be separately agreed with every police force en route. It is not unknown to be taken so far by one force then held for hours if the next force has an emergency that intervenes. Some forces also have restrictions on the timing of escorted loads, so delivery from works to site can be unpredictable, which may have implications in the timing of critical lifts.

Special order

If the vehicle and load to be moved fall outside the STGO categories it is still possible to move, but approval must be gained from the Highways Agency (or the Scottish Executive or Welsh Assembly Government) in the form of a VR1 Permit or a Special Order. All details of the load must then be notified to the Highways Agency, together with precise dispatch and delivery points. At least three months should be allowed between the first application for such a permit or order and the anticipated date of the actual movement.

A Special Order details the approved route and must be followed exactly. Special Orders are usually valid for 6 months. The specified notice must be given to each police region for the actual movement and to the relevant bridge owners on the route.

Clearly it is advantageous for designers to consider transportation when determining element sizes, and preferably limit the length and width of elements such that they comply with the ‘normal load’ rules. However, transportation of larger fabrications is commonplace under the ‘abnormal load’ rules, and specialist bridgeworks fabricators are experienced in the movement of very long girders using ‘special orders’.

Further guidance on the transport of steelwork by road is available in GN 7.06

Specification

Quality management

The steel construction industry and supply chain are able to call upon members of the BCSA and their inherent qualities of competency and professionalism, all demonstrated by among other things, the following:

- Register of Qualified Steelwork Contractors for Buildings (RQSC - Buildings)

- Register of Qualified Steelwork Contractors for Bridgeworks (RQSC - Bridgeworks)

- Steel Construction Certification Scheme (SCCS)

- UKCA Marking

- Steel Construction Sustainability Charter (SCSC)

- Steel Construction Building Information Modelling (BIM) Charter

Register of Qualified Steelwork Contractors for Buildings (RQSC - Buildings)

The RQSC - Buildings and RQSC - Bridgeworks requirements are more than just registers of companies selected from a tick list. Each company only qualifies for inclusion on the lists after being assessed by specialists who check financial, technical, and health & safety resources as well as track record and employed personnel. The assessments are carried out annually with a physical factory inspection every three years. The result is two criteria:

- Categorisation of the company in terms of the work it can execute technically

- Classification of the company in terms of the maximum size of contract it should handle

The assessments provide clients with an easy way to pre-qualify steelwork contractors for buildings and bridges before contracts are tendered. This ensures that the successful steelwork contractor has the special skills to suit the project, and helps the client to fulfill the regulatory duty only to use competent contractors.

The categories of work are general and the precise scope of work demanded by each project will differ. Thus, the first priority for competent contractors is to ensure that the scope of work can be safely undertaken with the resources of know-how, manpower, equipment and finance at their disposal. For this purpose two checklists of competences are available:

- Normal scope of competence for activities that steelwork contractors should be competent to undertake with their own personnel

- Special scope of competence for activities that steelwork contractors should be able to manage using specialist subcontractors as necessary

Having checked at tender stage what a project demands, steelwork contractors should warn their clients if they are unable to undertake any of the normal activities, and their clients should check beforehand whether a steelwork contractor is willing to undertake any of the special activities.

A separate Register operates to cover bridgeworks. Highways England includes in its Specification for Highway Works[12] a requirement that only firms listed on the Register of Qualified Steelwork Contractors for Bridgeworks (RQSC - Bridgeworks) for the type and value of work to be undertaken will be employed for the fabrication and erection of bridgeworks.

Steelwork contractors can be sourced according to the required project Class and Category on https://bcsa.org.uk/member-directories/

Steel Construction Certification Scheme

Quality Management System Certification (QM)

Quality management systems operated by the certified contractors are formally assessed to ensure compliance with the requirements of BS EN ISO 9001[4]. Each certificate is valid for three years during which period SCCS conducts interim surveillance audits to monitor continued compliance with the certified management system.

Environmental Management System Certification (EM)

Environmental management systems operated by the certified contractors are formally assessed to ensure compliance with the requirements of BS EN ISO 14001[13]. Each certificate is valid for three years during which period SCCS conducts interim surveillance audits to monitor continued compliance with the certified management system.

Occupational Health and Safety Management System Certification (HSM)

Occupational health & safety management systems operated by the certified contractors are formally assessed to ensure compliance with the requirements of BS ISO 45001[14]. Each certificate is valid for three years during which period SCCS conducts interim surveillance audits to monitor continued compliance with the certified management system.

UKCA Marking and Factory Production Control (FPC)

FPC systems operated by the certified steelwork contractors are formally assessed to ensure compliance with the requirements of:

- BS EN 1090-1[8] for structural steel

- BS EN 14399-1[16] for high strength structural bolting assemblies

- BS EN 15048-1[6] for non-preloaded structural bolting assemblies

Each certificate is valid for three years during which period SCCS conducts interim surveillance audits to monitor continued compliance with the certified FPC system.

National Highway Sector Schemes (NHSS)

SCCS has been accredited by UKAS to carry out assessments against:

- NHSS 3 [17] – The stocking and distribution activities for mechanical fasteners

- NHSS 3B [18] - The stocking and distribution activities for structural steel products

- NHSS 19A[19] – For corrosion protection of ferrous materials by industrial coatings

- NHSS 20[20] – The execution of steelwork in transportation infrastructure assets

Each certificate is valid for three years during which period SCCS conducts interim surveillance audits to monitor continued compliance with the certified NHSS.

Steel Construction Sustainability Charter

In 2005, the British Constructional Steelwork Association (BCSA) became the first representative organisation in the UK to launch a Sustainability Charter. This was updated and strengthened in 2021 in response to the climate emergency. The objective of the Charter is to further advance steel as a sustainable form of construction in terms of carbon reduction, reuse and efficiency, economic viability, social progress and environmental responsibility. BCSA has four levels of status under the Charter, i.e. Certificate, Bronze, Silver and Gold, the status achieved depending on the number of points scored following audit against 15 requirements. BCSA Member and Associate Member companies that agree to be bound by the charter have to make a formal declaration of their commitment to a set of sustainable principles and are assessed and monitored against a range of environmental, social and economic criteria.

BCSA requires Charter Members to formally declare to operate in sustainable ways that work towards:

- Adding value to clients and stakeholders

- Optimising the eco-efficiency of steel construction life cycle

- Promoting resource and energy efficiency in steel construction through reuse and recycling

- Operating in a safe, healthy and environmentally sound manner

- Promoting respect for people and communities associated with steel construction; having high ethical standards

The Charter has been used to help improve understanding of sustainability among steel construction companies and to help them manage their businesses in more sustainable ways.

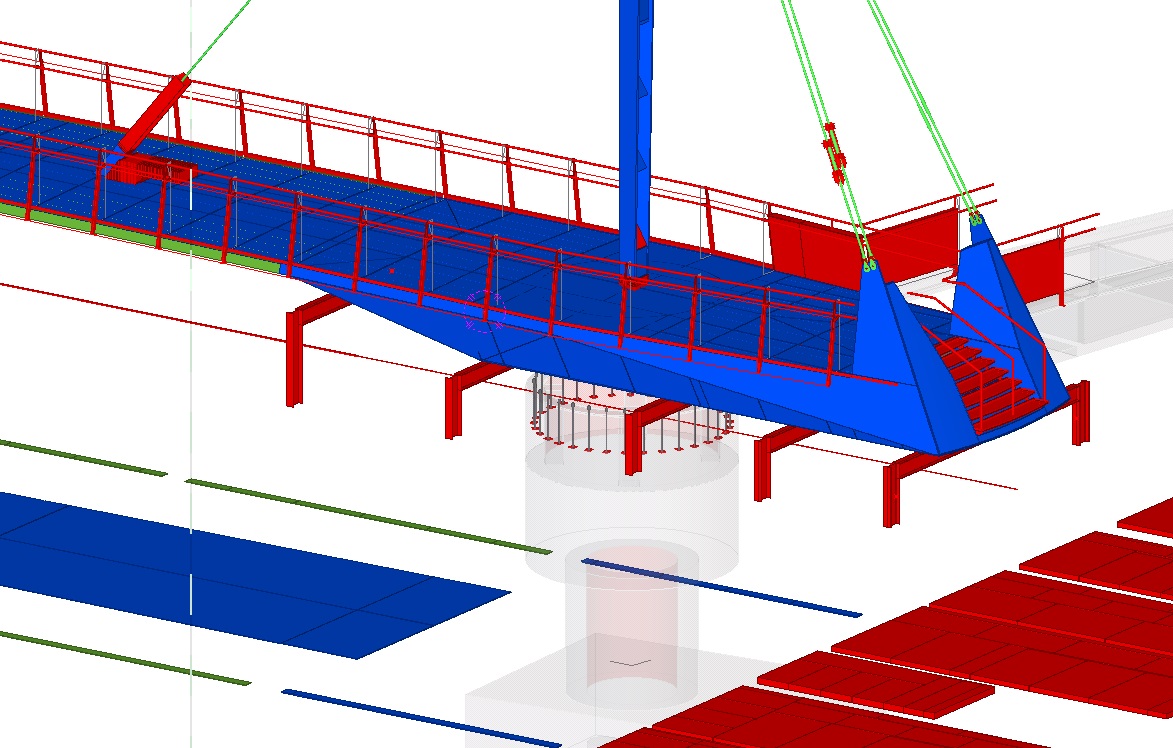

Steel Construction Building Information Modelling (BIM) Charter

(Image courtesy of S.H.Structures Ltd.)

BCSA steelwork contractors can demonstrate compliance through the Steel Construction BIM Charter, which enables companies to be certified against the requirements of both PAS 91[21] outlined below by achieving BIM according to the BS EN ISO 19650 series.

Steel Construction BIM Charter membership certifies compliance with PAS 91[21] section 4.2 table 8, and specifically that:

- The company has the capability of working within a project using a ‘Common Data Environment’ as described in BS EN ISO 19650-2[22].

- The company has a documented policy, systems and procedures to achieve Stage 2 maturity as defined by BS EN ISO 19650-1[23].

- The company has the capability of developing and delivering or working to (depending upon the role(s)) a BIM Execution Plan (BEP) as described in BS EN ISO 19650-2[22].

- The company has arrangements for training employees in BIM related skills and assessment of their capabilities.

Steel Construction BIM Charter membership also certifies compliance with PAS 91[21] section 4.2 table 7 question O3-Q6 through the supply chain assessment requirements stated in section 5.3.3 of BS EN ISO 19650-2[22] and specifically considering the following:

- Suppler BIM assessment – 5.3.3a)-b)

- Supplier information technology (IT) assessment – 5.3.3c)

- Supplier resource assessment – 5.3.3a)-c)

The certification process requires companies to carry out an online assessment, which is then followed up by an onsite audit. Certified companies are provided with a comprehensive document summarising the company’s BIM capability, which they can then provide to the supply chain.

The BCSA’s online directories mean clients and main contractors can see which companies have been assessed against the BIM Charter, with the Charter providing a simple way to prequalify steelwork contractors as BIM compliant.

Health and safety

The use of automated and semi-automated multi-function machines that cut, drill and mark the steelwork reduces the number of people involved in the process and the need to handle the steel i.e. turning and repositioning is reduced. These processes also reduce the risk of error and the need for re work to take place on site where even minor alterations may need lots of additional access or plant and equipment to be mobilized.

Generally the fabricated item moves through the production area until completed and then stored. On construction sites the equipment (often temporary) has to be brought to the final position of the item and then moved each time, all of which increases risk of incidents as lots more moving and repositioning needs to take place.

Working within a factory eliminates any health and safety issues concerned with adverse weather conditions and production can continue. This also gives additional advantage for longer hours of production including night shift work if necessary, all of this in a controlled environment with no disruption to the local communities.

Pedestrian access and egress is controlled by permanent marked routes which are separate from the vehicular routes. Loading and unloading of steelwork is carried out in designated areas with the appropriate access and lifting equipment.

The systems used to programme the production of fabricated steelwork mean that the work can be packaged, this enables the deliveries to site to be managed in such a way that offloading can be direct to the final position. This reduces site storage and minimizes lifting and handling where most risks of incidents and injuries can be presented.

Relevant Steel for Life sponsors

This website is maintained by Steel for Life with funding provided by a number of BCSA’s Industry Members. Those sponsors relevant to this article are as follows:

|

Gold |

|

|---|---|

|

Jamestown are a top tier supplier of structural components to the fabrication, rail & highways sectors. Long experienced in heavy engineering, Jamestown have invested heavily in equipment dedicated to manufacture of heavy long span bridges, plate girder carcasses, fully fabricated plate girders, crane components, bridge deck sections, cellular beams etc. |

|

Silver

Resources

- National Structural Steelwork Specification (7th Edition), 2020, (Publication No. 62/20), BCSA

- Corrigenda - First Revision National Structural Steelwork Specification (7th edition), 2023, (Publication No. 67/23), BCSA

- Commentary (3rd edition) on the National Structural Steelwork Specification for Building Construction (7th edition), 2022, (Publication No. 66/22), BCSA

- Typical Welding Procedure Specifications for Structural Steelwork - Second Edition, 2018, (Publication No. 58/18), BCSA

- High Strength Steels for Structural Applications: A Guide for Fabrication and Welding, 2020, (Publication No. 63/20), BCSA

- Steel Buildings, 2003, (Publication No. 35/03), BCSA

- Chapter 9: Welding

- Chapter 10: Bolting

- Chapter 11: Fabrication

- Chapter 15: Specification and Quality

- Design for Manufacture Guidelines (P150), 1995, SCI

- Steel Bridges: A practical approach to design for efficient fabrication and construction, 2010, (Publication no. 51/10), BCSA

- Chapter 4 Bolting

- Chapter 5 Welding

- Chapter 6 Accuracy

- Chapter 7 Costs

- Allocation of Design Responsibilities in Constructional Steelwork, 2007, (Publication no. 45/07), BCSA

- Hydrogen Embrittlement - Its effect on Structural Bolting Assemblies, 2022, BCSA

- Model Specification for the Purchase of Structural Bolting Assemblies and Holding Down Bolts, Issue 14, BCSA, 2023

- Model Specification for the Purchase of Structural Tension Assemblies, BCSA, 2015

- Health and Safety in the Workshop for Employees: A Guide for Steelwork Contractors, 2009, (Publication no. 49/09), BCSA

- Guide to Work at Height during the Loading and Unloading of Steelwork, 2007, (Publication no. 43/07), BCSA

- Normal scope of competence, BCSA

- Special scope of competence, BCSA

- Design of curved steel (P281), 2001, SCI

- Hendy, C.R.; Iles, D.C. (2015) Steel Bridge Group: Guidance Notes on best practice in steel bridge construction (6th Issue). (P185). SCI

- Guidance Note 4.02 Weld procedure tests

- Guidance Note 5.01 Weld preparation

- Guidance Note 5.02 Post-weld dressing

- Guidance Note 5.03 Geometrical tolerances

- Guidance Note 5.04 Plate bending

- Guidance Note 5.05 Marking of steelwork

- Guidance Note 5.06 Thermal cutting of structural steels

- Guidance Note 5.07 Straightening and flattening

- Guidance Note 5.08 Hole sizes and positions for preloaded bolts

- Guidance Note 5.09 The prefabrication meeting

- Guidance Note 6.01 Control of weld quality and inspection

- Guidance Note 6.02 Surface inspection of welds

- Guidance Note 6.03 Sub-surface inspection of welds

- Guidance Note 6.04 Hydrogen / HAZ cracking and solidification cracking in welds

- Guidance Note 6.06 Visual inspection after welding

- Guidance Note 7.06 Transport of steelwork by road

Further reading

- Steel Designer’s Manual (7th Edition), 2012, Chapter 33 - Fabrication, The Steel Construction Institute.