Various generic forms of connection may be used in steel frames. These include:

- Beam-to-column flange connections that may be moment-resisting

- Beam-to-beam web connections that are normally designed as nominally pinned

- Column-to-column splices

- Column bases at foundations

- Bracing connections.

Connection detailing depends on the forces and moments to be transferred, and on the chosen member sizes. However, some common detailing rules apply, which are discussed below, in order to gain an appreciation of the form of connections in regular frames.

Conventional connection types

Main articles: Braced frames, Continuous frames, Simple connections, Moment resisting connections

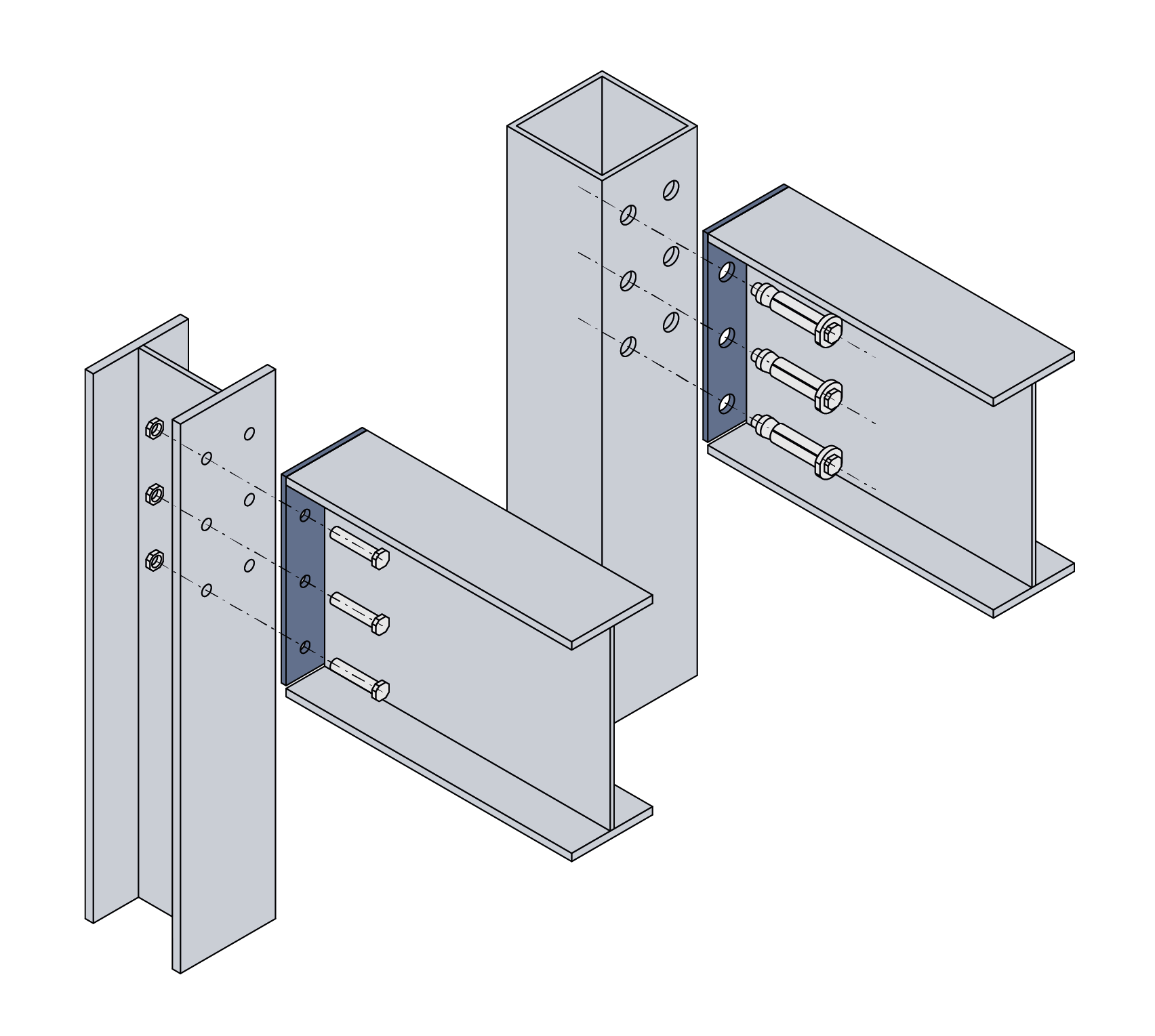

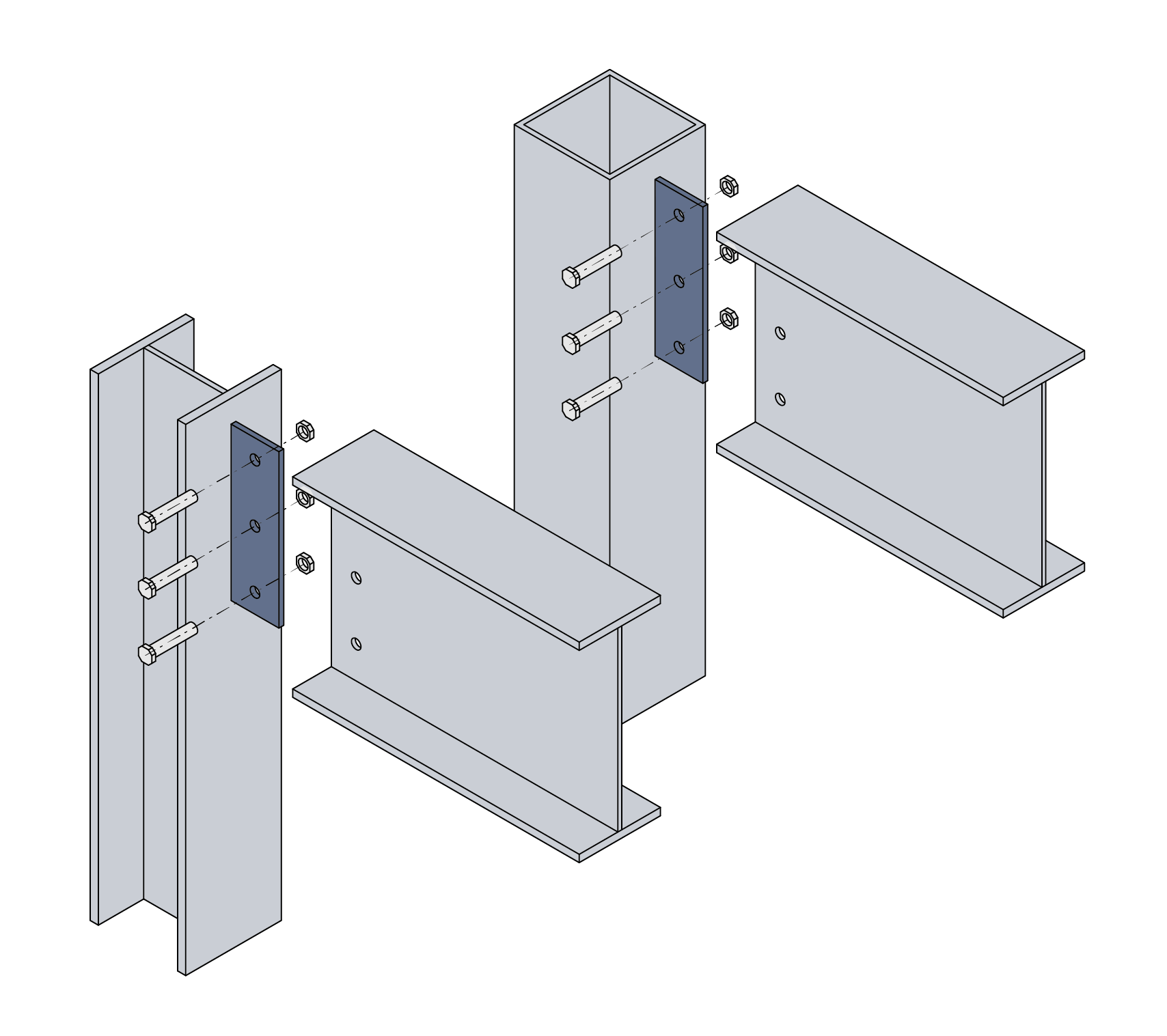

For connections to Square Hollow sections (SHS), a form of expansion bolt connection may be used that forms a connection by expanding into the space behind the face of the section. However, the diameter of the expansion part of the bolts is up to twice that of the bolt diameter and so the spacing between the bolt holes has to be increased compared to normal bolts. Alternatively, proprietary 'blind' fixings may be used.

Tubular connections

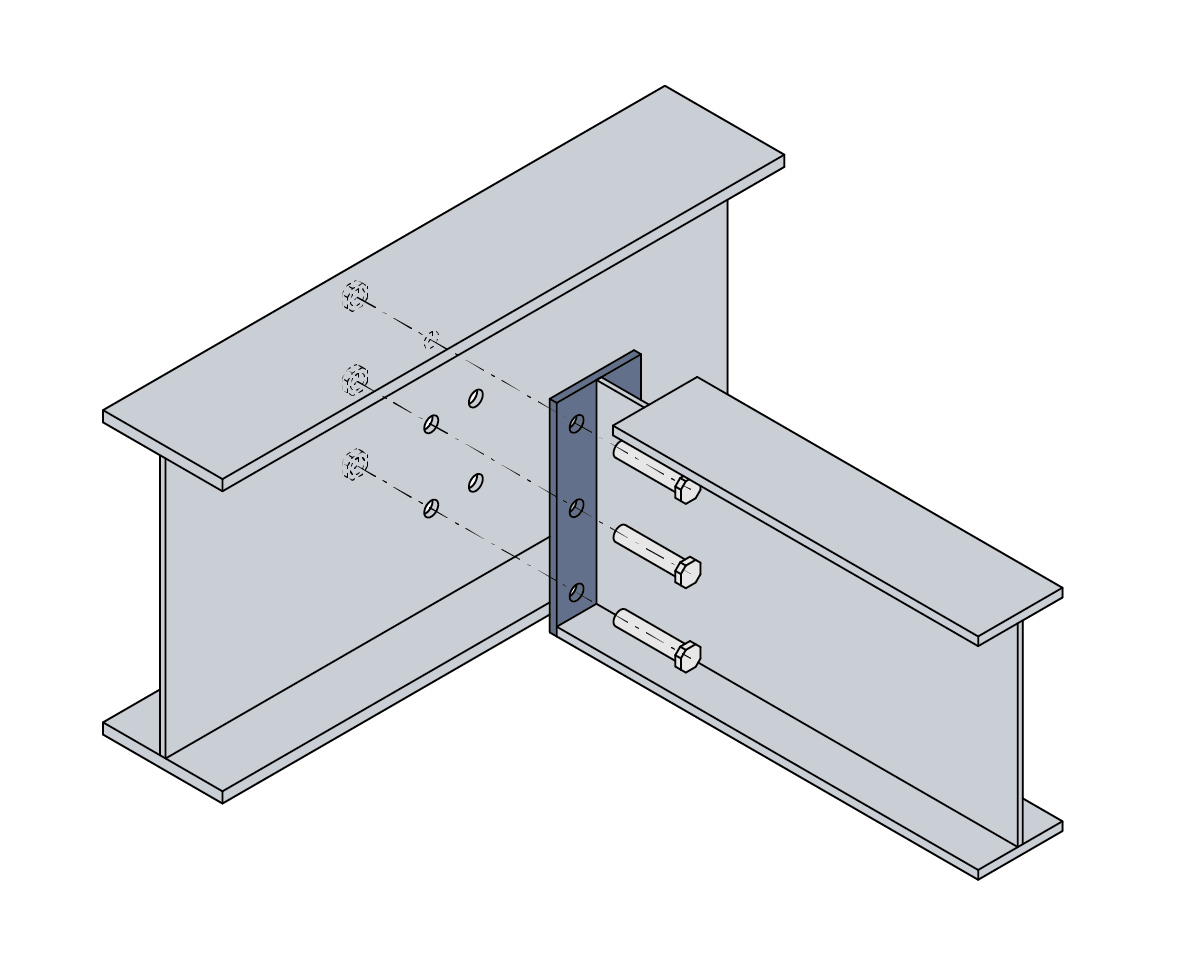

- Beam-to-column connections that are usually bolted

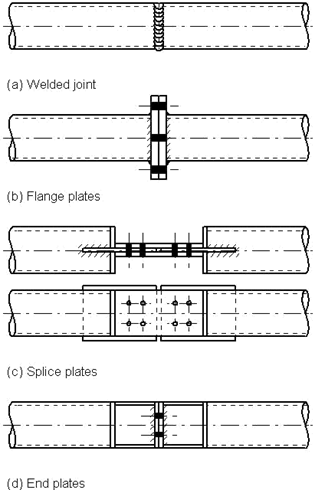

- In-line connections that may be bolted or welded. In-line connections often occur in long members that require splicing for transportation.

- Tubular sections with welded fins

- Inclined connections such as inclined bracing to horizontal chords. These are usually welded.

The chords and bracing in a truss or lattice girder are often welded.

The figure shows the use of a shaped fin plate to provide more visual appeal to an otherwise simple connection between the top chord and bracing of a deep truss.

A profiled cover plate may be provided so that the connection is not visible, as shown below.

Tie connections

- Couplers which require that the rods are threaded in opposite directions so that the coupler can be tightened.

- Pins which may be welded to the rods or provided with threads. The pin is normally connected to a fin plate that is welded to another member.

Rods and couplers are often stainless steel if exposed externally. Good examples of stainless steel tie rods used in the external façade of the Helsinki Sanomat building are shown. Where multiple connections between tie rods are required, special castings or fabricated nodes are necessary.

Rods may be connected by various types of cast and formed nodes. The detail shown is supported from above by a threaded rod and the horizontal nodes allow for articulation in two directions.

Sanomat Building, Helsinki

Further reading

- Steel Designers' Manual 7th Edition. Editors B Davison & G W Owens. The Steel Construction Institute 2012, Chapter 27, Joint design and simple connections

- Architectural Design in Steel – Trebilcock P and Lawson R M published by Spon, 2004

- Steel Buildings, BCSA No. 35/03, Chapter 4, Multi-Storey Buildings

Resources

- SCI P167 Architectural Teaching Resource Studio Guide, 2000

- Best Practice in Steel Construction: Commercial Buildings

- Steel Buildings in Europe - Multi-storey buildings:

- EP37 Best Practice in Steel Construction – Industrial Buildings, Guidance for architects, designers & constructors

- Steel Buildings in Europe - Single storey buildings:

- SCI P358 Joints in Steel Construction - Simple Joints to Eurocode 3, 2014

- SCI P398 Joints in Steel Construction - Moment-resisting Joints to Eurocode 3, 2013

- Design of welded joints - Celsius®355 and Hybox®355, 2013, Tata Steel