Article in NSC May 2018

The racing day experience at Hampshire’s Thruxton Circuit has been enhanced by a new £1.5M steel-framed hospitality suite.

Forming the cornerstone of a wider redevelopment programme, Thruxton’s new steel-framed two-storey hospitality complex includes a restaurant, bar, exhibition gallery, function rooms, hospitality suites, catering facilities, viewing terraces and a balcony.

Featuring an innovative design, which fully utilises steelwork’s aesthetic qualities by leaving the majority of the framing material exposed, it also includes a grand atrium and entrance lobby said to reflect the dynamism of motorsport as well as the circuit’s rich heritage. Initially designed by architects Chapman Partnership, they and the client always envisaged the scheme being built as a steel-framed structure.

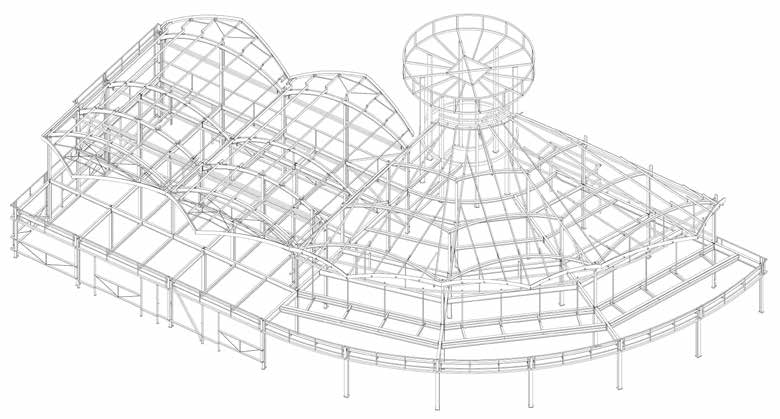

The building’s shape has two distinct conjoined parts, one curved and shaped like an open fan on plan, and the other a more traditional rectangle. Both parts are topped by a series of curved barrel-vaulted roofs, which cantilever over a balcony that wraps around the front of both parts and overlooks the racing circuit.

Working on a design and build contract for the project’s steelwork, cladding and glazing, REIDsteel helped to rationalise the design by working collaboratively with the rest of the design team to ensure they had a steel frame that could be built easily on-site. “We made a number of refinements to the steelwork,” explains REIDsteel Structural Engineer John Harrison. “Most notably, omitting some large roof beams and introducing cantilevering purlins instead. As the purlins are hidden in the sheeting, it gives the illusion of no roof support for the cantilever, as well as being a more cost-effective design.”

Steelwork for the 1,415m2 hospitality centre is based around a regular grid, albeit one that radiates inwards around a constant radius on one side of the structure to form the fan-like area. To form the roof of the fan, four rafters splay out from a central point, supporting the curved members that form the barrel-vault.

The structure has minimal internal columns, creating open-plan areas and maximum flexibility, with spans generally up to 10.5m-long. Stability for the structure is provided by semi-continuous frames for the ground floor, while the first floor is a mix of portalised and tied barrel roofs. “The requirement to keep the steelwork exposed within the completed building dictated the stability system we chose for each floor,” explains Mr Harrison. The upper level has a lot of glazing and so an unobtrusive portal frame was deemed to be the most effective method.

At the rear of the building, positioned at the point where the curved fan-like part connects to the rectangular part of the building, there is an 8m-diameter round turret that contains the main staircase. The staircase is attached to the roof of the turret via a series of Macalloy rods. Because the stairs also provide a fire escape route, the rods are deemed to not offer enough support so the staircase also cantilevers off the side of the turret. The turret is a facetted circle formed with 16 straight sides. This negated the need for more expensive curved members and made the installation of the glazing easier, as curved glazing panels are also expensive.

Mr Harrison says: “Thruxton wanted an innovative and modern hospitality centre to reflect its status as one of the most iconic racing venues in the UK. “Having designed, manufactured and supplied stadia for a wide range of clients, we are delighted to have delivered this landmark project which will support the venue’s growth for years to come.”

|

'Architect' |

Chapman Partnership |

|

'Steelwork Contractor' |

REIDsteel |

|

'Main Contractor' |

Mata Construction |

|

'Main Client' |

British Automobile Racing Club |