Papdale Halls of Residence, Kirkwall

Future flexibility

Steel construction proved to be the most cost-effective and economical option for new halls of residence at Kirkwall Grammar School on the Orkney Islands.

Structural steelwork is prefabricated and can be delivered to site in manageable loads, whatever the distance is from fabrication facility to the project. Steel is also quick to erect and this is always an advantage on a project where windy conditions can arise and potentially disrupt the construction programme at any time. These benefits, and more, have all played a significant role in the construction of the Papdale Halls of Residence at Kirkwall Grammar School on the Orkney Islands.

As part of a multi million pound schools investment programme for the islands main contractor, Morrison Construction is also delivering an adjacent new grammar school, a swimming pool and squash courts, and a primary school in Stromness.

In conjunction with the adjacent school build programme, Papdale is scheduled for completion in May. Morrison has been on the overall site since mid 2011, but work on the halls only started in March 2012. Early works included levelling the sloping plot and then installing foundations in preparation for the steelwork erection to begin in March.

Steelwork contractor BHC, who has also erected the 1,200t steel frame for the grammar school, completed the halls in just three weeks. “The speed of steel construction was one of the main reasons for choosing the material,” says Ronnie Bruce, Morrison Construction Project Director. “We looked at all options and even if we’d have had to stop erecting steel for a period due to windy conditions, it was still the best and most cost efficient framing option.”

Working on a location such as the Orkney Islands means all materials have to be transported from the mainland, with the steelwork arriving by ship from Aberdeen. “Steel is more adaptable than other materials as it can be shipped to site in small loads,” comments Alastair Kinghorn, Keppie Project Architect. BHC had to limit the steel deliveries to 25t truckloads, which were taken by road from its South Lanarkshire fabrication facility to the port at Aberdeen. Once shipped to Kirkwall, the steel loads were held in a compound until required on site.

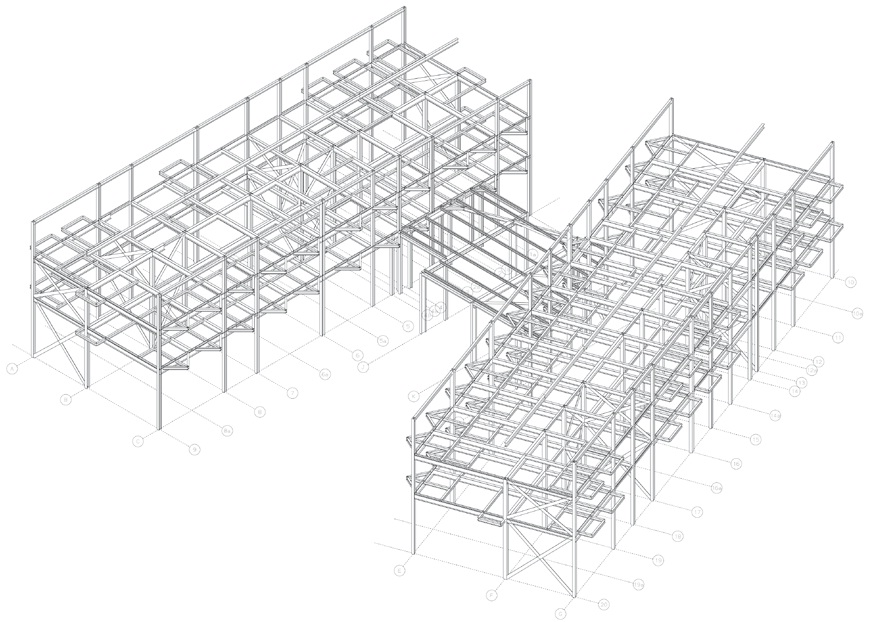

The two blocks are of similar size and are constructed as steel braced frames supporting metal decking for the slabs. Bracing is located in gable ends and in the lift cores and stairwells. Steel beams and columns are based around a fairly regular grid pattern of 3.75m × 3.75m, with alternate bays larger in one direction at 3.75m × 6.75m. “It’s a lightweight frame and for economic reasons the design has allowed the omission of alternate columns,” explains Mr Kinghorn.

Summing up, Mr Moar adds: “By using steel we have also given ourselves the flexibility to extend the halls if necessary. An extension could simply be bolted on to the existing frame.”

All in the detail

Steel was the only material for this tricky design criteria,” says Alastair Kinghorn, Keppie Project Architect. “To form these bays in any other material would have been costly and labour intensive.” All of the bay windows, straight units for the outer façades as well as the angled units, were prefabricated by BHC and brought to site as complete pieces. This speeded up construction as they were simply and quickly lifted and bolted into place.